| |

|

|

| |

超高濃度真空乳化攪拌機 (T.T-AGI)

Emulsifying Mixers High-Speed Viscosity Vacuum |

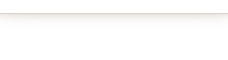

■ Machine introduction:

| |

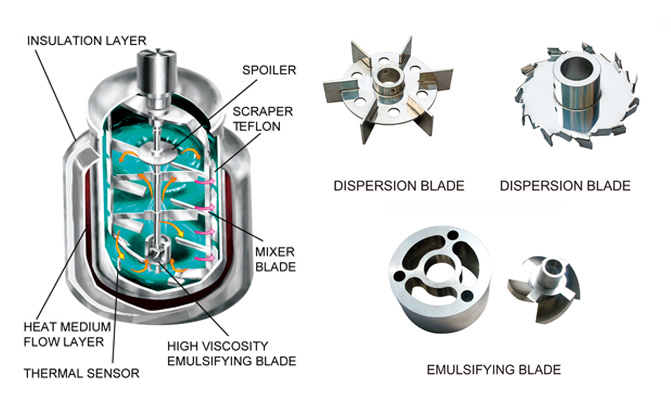

The high-speed emulsification and low-speed mixing functions allow integration of both heating and cooling in a same process to achieve economical and safe production for each product. The scraper blade and powerful emulsifying blade work perfectly together to repeat squeezing and mixing of raw materials. The powerful high-speed turbo blades perform cutting, circulating convection, shredding and squeezing to disperse and re-polymerize the raw materials for proportionate and refined molecules. The equipment makes the raw materials proportionate and product smooth with beautiful shinny colors as it is effective in proportioning and emulsifying fine particles. |

■ Machine features:

| 1. |

The machine completes emulsification, stirring, mixing and dispersion in a very short time. |

| 2. |

The machine performs stirring, emulsification, heating, vacuum degassing and cooling for continuous operation to simplify production process and save manpower and time. |

| 3. |

Teflon scrapers (for avoiding softening which affects convection during stirring) are easy to disassemble for preventing cross-contamination and easy cleaning and maintenance. |

| 4. |

Beveled scraper provides excellent stirring and is easy to clean. |

| 5. |

The tank bottom ball valve has no blind space, which allows proportionate emulsification of raw materials and convenient cleaning. |

| 6. |

The parts exposed to with liquid are all made of SUS316 stainless steel. |

| 7. |

The machine is multifunctional as the emulsifying blade or mixing blade can be designed based on the customers’ needs (easy replacement and operation). |

| 8. |

With the vacuum design, raw materials are sucked into the tank to avoid contamination. |

| 9. |

Sophisticated power control design allows easy operation and stable performance. Safe switches are equipped for machine operation. All safety devices are interlocked to ensure a 100% public safety. |

| 10. |

The polish degree of the parts in contact with the processed materials is over #500, and the appearance can be finished dull or glossy, providing excellent efficiency for maintenance and cleaning of the machines. A polish certificate is attached. |

| 11. |

Automatic operation process, control interface and digitalized display. The machine complies with the annual verification and calibration standards. Easy operation and maintenance, no skilled technicians are required. |

| 12. |

For automatic operation, you can choose a more economical traditional model or a zero-error model with PLC and man-machine interface for touch-control, the function to set up multiple production processes and the capability to record processing conditions to ensure stable product quality and accurate production. |

■ For production of:

Dyes and textiles: |

dyeing paste, weaving paste, textile printing paste, resin paste for resin processing, dyes, textiles, production and fiber grease, etc. |

Chemical fibers: |

all kinds of synthetic and chemical fibers. |

Printing chemicals: |

emulsifier additives, paste, ink, printing dyes, etc. |

Chemicals: |

pigment, dyes, transfer printing materials, other industrial chemicals. |

Foods: |

all kinds of emulsified stablizer, grease, milk, drinks, lactic acid bacteria drinks, butter, jam, seasonings, etc. |

Medicine: |

all kinds of ointment, emulsion, injection liquid, syrup, liquid medicine. |

Cosmetics: |

lotions, stearic acids, emulsifiers, spices, plant oils, face soaps, facial creams, face mask liquid, oil-based white powder, lipsticks, hair conditioners, etc. |

Paints: |

water-based paints, oil-based paints, synthetic resin paints. |

Others: |

adhesives, single-color dyes and pulp. |

■ Flow Chart:

■ Specification:

型式

MODEL |

全容量

FULL VOLUME |

|

攪拌馬達

MIXER MOTOR |

外型尺寸 OUTSIDE DIMENSION (MM) |

馬力 H.P. |

轉速

R.P.M |

馬力 H.P. |

轉速

R.P.M |

長

LENGTH |

寬

WIDTH |

高

HEIGHT |

全高

MAX. H |

T.T-AGI-5L |

5 LITER |

1/2 |

1000~11000 |

1/4 |

10~60 |

750 |

300 |

1350 |

1350 |

T.T-AGI-10L |

10 LITER |

1 |

1000~10000 |

1/2 |

10~60 |

950 |

690 |

1650 |

2100 |

T.T-AGI-80L |

80 LITER |

2 |

550~3600 |

1 |

10~60 |

1850 |

670 |

2100 |

2850 |

1750 |

1045 |

T.T-AGI-100L |

100 LITER |

3 |

550~3600 |

1 |

10~60 |

2200 |

750 |

2150 |

2950 |

T.T-AGI-150L |

150 LITER |

3 |

550~3600 |

2 |

10~60 |

2050 |

1325 |

2150 |

3050 |

T.T-AGI-250L |

250 LITER |

5 |

550~3600 |

2 |

10~60 |

2580 |

980 |

2450 |

3650 |

2300 |

1545 |

T.T-AGI-300L |

300 LITER |

5 |

550~3600 |

2 |

10~60 |

2480 |

1050 |

2700 |

3750 |

T.T-AGI-400L |

400 LITER |

7-1/2 |

550~3600 |

3 |

10~60 |

2720 |

1660 |

2800 |

4030 |

T.T-AGI-650L |

650 LITER |

10 |

550~3600 |

5 |

10~60 |

2950 |

1960 |

2800 |

4100 |

T.T-AGI-1000L |

1000 LITER |

15 |

550~3600 |

7-1/2 |

10~60 |

3200 |

1530 |

3650 |

5400 |

|

* Special dimensions can be custom made pursuant to the customer needs.

* Ta Teng reserves the right to modify the specifications without notice.

TOP TOP

|

|

|

|